Our

Fabric

Our process

The secret of our success lies in our attention to detail and our commitment to quality.

Our process begins by searching the world for the highest grade, extra-long staple cotton. Only the very best of the world’s cotton crop meets our exacting standards and it is with this small 2% that we make Ventile®. A further 0.04% of this 2% is used to make Ventile® organic cotton.

The cotton fibres are picked, sorted and carefully spun into an even, uniform yarn. High precision spinning results in a streamlined yarn which is essential for giving Ventile® its unique waterproof characteristics. After spinning, the yarn is then doubled in order to increase its durability and abrasion resistance.

This tough yarn is then wound onto cones for ease of handling. The strands from over 700 cones are then looped onto back beams for sizing – a natural treatment process which prepares the threads for compressive weaving. Over 15,000 individual strands of yarn are then threaded onto the loom and woven into a fabric, a process which takes precision and many hours to complete.

The resulting Ventile® fabric is then carefully inspected by our team of textile experts who run several tests to expose potential faults. Following this inspection, which is always done by hand, only 100% ‘Grade A’ fabrics are sent off for dyeing and finishing.

Due to the incredibly dense structure of the fabric, Ventile® is pre-treated and dyed using a specifically developed process to ensure the best possible dye penetration, whilst avoiding creases, stains, stripes and shading which would affect the end product. Even on modern dyeing machines, the Ventile® dyeing process is a challenge to be mastered.

After dyeing, the fabric is finally treated with a durable water repellency finish (DWR) on both sides of the fabric for added performance and water resistance.

To ensure the highest technical specifications of our product is always met, Ventile® is subject to strict inspection procedures and laboratory testing throughout all stages of processing, all of which guarantee an exceptional end product.

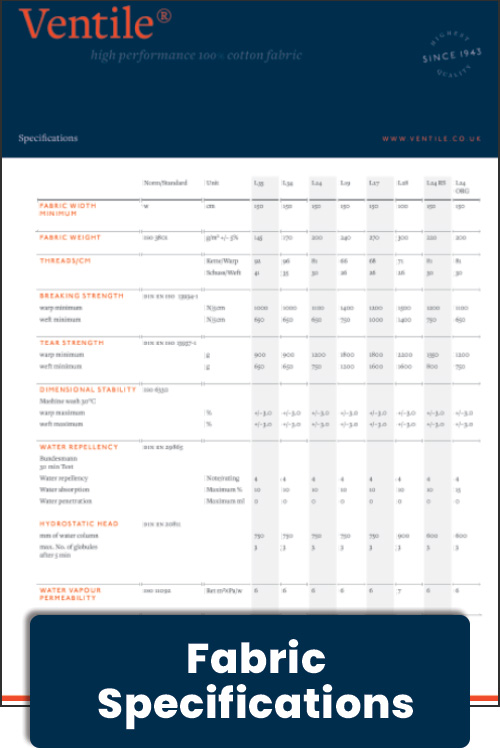

Ventile fabric technologies are amongst the most hard wearing, durable and reliable in the world. Please find details on our fabric specifications here.

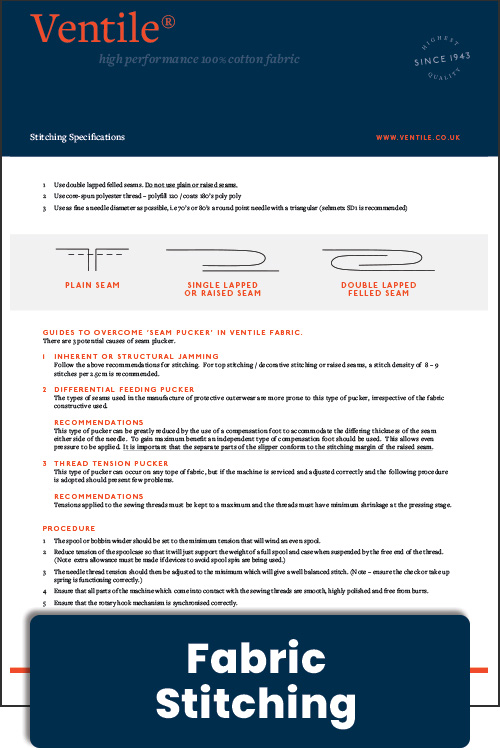

For information on how to work with the fabric, stitching specifications and instructions, click here.

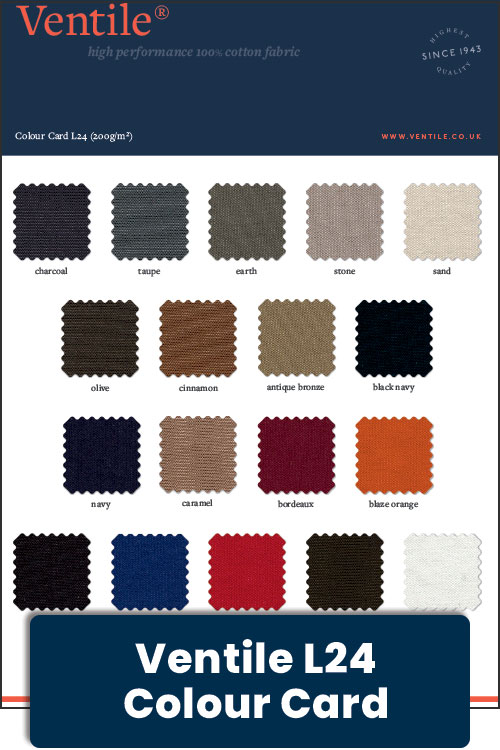

For more information on the different colour specifications available in Ventile fabric, click here.

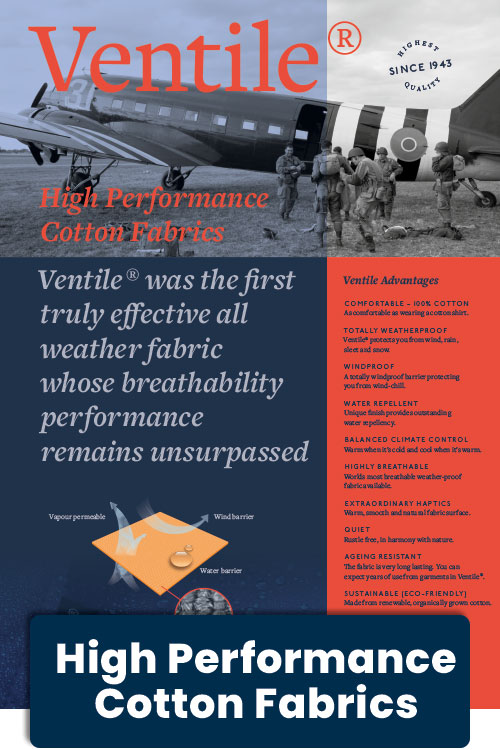

For more information on the advantages of Ventile fabric, click here.