Q and A's

Recent developments in fabric technology mean now is the time to move away from the use of PFCs which are known to result in an unnecessary environmental cost. This is the natural next step for our brand which has been long committed to sustainable practises, with any potential impact on the environment always being a key consideration. This is a historic move forward for our brand as we continue to strive to improve our environmental and social impact at every stage of the process.

Over the last two years, we have worked closely with scientists, textile experts and dye houses to find a DWR replacement for PFCs that doesn’t compromise the quality of our fabric or shorten its lifespan. Through rigorous testing in both the lab and field, our new PFC-free DWR continues to deliver the performance specifications relevant for the end-user.

Spinning: EU, Egypt, Turkey

Weaving: EU, Egypt, Turkey

Dyeing/Finishing: Switzerland

The DWR is based on Dendrimer technology and is developed from a renewably sourced, non-fluorinated durable water-repellent finish. This breakthrough product is the industry’s first and only renewably sourced water repellent treatment. The new finish contains 63% renewably sourced content derived from a variety of plant-based sources, carefully selected from non-genetically-modified (non-GMO) and non-food-source feedstock.

The DWR is impregnated using the traditional method of immersion. The dyed fabric is then dipped into an immersion bath of this specially crafted PFC-free solution before passing through the stenter frame and left to dry.

Initial tests suggest that the PFC-free fabric has the ability to break down faster than before. At eight weeks in laboratory testing, the fabric can be seen to break down.

Occasionally, there may be minor shade differences due to the density of the fabric restricting full dye penetration. The way in which the fabric is woven means it absorbs considerably less dye (approx. 30%) in comparison to other dense cotton (approx. 70%-80%).

In this sense, each batch is unique, and it can be difficult to create an identical match every time. Despite this, through regular testing and thorough inspections, we always strive to achieve the highest level of consistency throughout the production of each batch of Ventile fabric.

Ventile is a durable fabric which is designed to withstand daily wear. That said, when natural cotton is repetitively worn and/or washed, it may start to appear weathered. The ‘aged’ look showcases the natural fibres of the fabric.

If you would like to maintain the original look of the fabric, we would recommend using a professional dry-cleaning service to care for your garment.

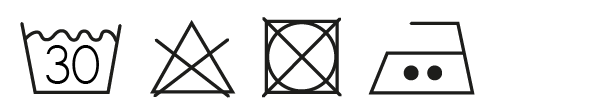

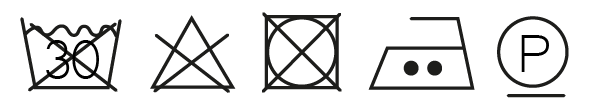

For your own individual garment, it is important to check the care label. Where possible, it is recommended that garments are professionally dry cleaned.

That said, we have included two separate care instructions below to achieve the most sought-after looks for Ventile garments.

‘As Good As New’

To maintain the original appearance of your Ventile garment, we would recommend washing it only when absolutely necessary, and by using a ‘gentle’ professional dry-cleaning service. Never use a washing machine or chemicals to clean it as doing so will ‘age’ the fabric.

Using a specialist service will not only ensure the garment remains in ‘as good as new’ condition, it will also help it retain its rainproof properties.

‘Traditionally Weathered’

To ‘age’ your Ventile garment and achieve a traditionally weathered look, we would recommend placing the item in a washing machine without any fabric softener or bleach. Run a cycle at a maximum temperature of 40°C. After each wash the fabric will begin to ‘age’. Continue until you reach your desired effect.

Please bear in mind after washing the garment a number of times it will no longer be rainproof. You can restore its Durable Water Repellency (DWR) by using products such as Nikwax Cotton Proof, which has been specially designed for use on cotton.

Ventile fabric is impregnated with a high quality Durable Water Repellency (DWR) treatment to enhance the fabric’s water resistant properties and increase performance.

Using a ‘dipping technique’, the Durable Water Repellency (DWR) treatment is applied to the fabric. To activate and ‘set’ the treatment, the fabric is heated to 180°C for 90 seconds. Finally, the fabric is sanforized in order to reduce the amount of shrinkage that would otherwise occur after the first wash.

In season fabric:

Providing the chosen fabric is available at the time of ordering, please allow up to 5 working days for delivery.

New colours/batches of fabric:

Please allow up to 5-6 weeks for delivery.

Fiber Source: Turkey

Stage: preconsumer, postindustrial

Spinning: Turkey

Weaving: Turkey

Dyeing/ Finishing: Switzerland

Certificate: GRS

Items available:

Ventile ECO 230 RCO

Ventile ECO 250 RCO

Ventile ECO 300 RCO

Ventile ECO 400 RCO

Ventile ECO 430 RCO

Hemp fibres have superior proprieties such as strength and durability and is physically much more resilient and longer lasting than cotton. The fast-growing plant, which requires very little water and no herbicides or pesticides to grow, produces one of the most environmentally friendly fibres available.

New for 2020, we have blended hemp fibres with Ventile’s extra-long staple organic cotton to produce Ventile Eco Hemp fabric. Combining superior properties from the organic cotton and hemp fibres has resulted in a high performance fabric, which is kind to the environment. In addition, the fabric has a natural texture which ages well as the more you wear it, the softer it becomes.

For more information on hemp fibres please visit our blog on Ventile Eco Hemp