Our

History

A lasting legacy

Ventile® was created to save the lives of Air Force personnel flying over the Atlantic in wartime England. Pilots needed a garment that was cool and comfortable in the cockpit, but warm and impenetrable if it came into contact with water. With nothing that offered this functionality on the market, a team of dedicated scientists pioneered a radical solution at the Shirley Institute in Manchester and, after several months of testing, Ventile® was born.

Ventile® extended life expectancy in the sea tenfold, which made rescue a real possibility. 80% of pilots who fell into the sea would now survive. Our fabric went into mass production in 1943 and was worn by RAF pilots around the world.

The unique weatherproof qualities of the fabric ensured that it was also widely championed by outdoor enthusiasts and adventurers alike. Ventile® was used in the first summit of Everest in 1953 and by Sir Ranulph Fiennes when he crossed the Arctic from 1979 – 1982.

After years of commitment to innovation, performance and protection from the elements, we continue to work with various air forces, as well as some of the most prestigious lifestyle and outdoor brands in history.

A story of collaboration

Late 1930’s

Ventile® was developed by a dedicated team of scientists from the Shirley Institute in Manchester with the original intention of being a substitute material for the construction of fire-hoses.

1939 to 1943

Wartime England was in full swing, with pilots flying over the Atlantic in need of a garment that was both comfortable in the cockpit, but also protective should they hit the water. That’s where Ventile® fabric was born.

1943

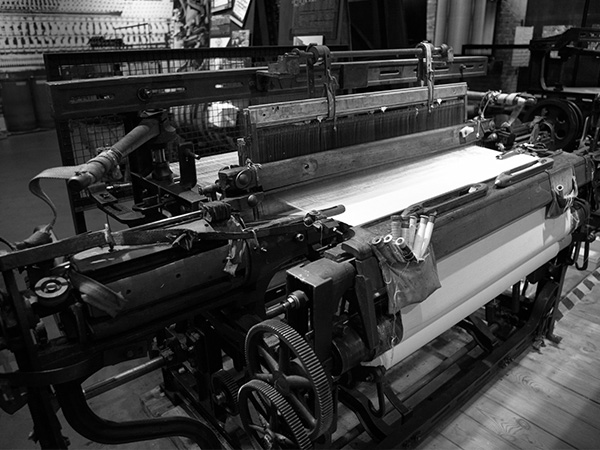

Ventile® went into mass production and was woven on huge wooden looms by Talbot Weaving in Chorley on the outskirts of Manchester, England.

1953

Sir Edmund Hillary reached the world’s highest point on the first summit of Everest in a garment made of Ventile® fabric.

1979 to 1982

Adventurer Sir Ranulph Fiennes crossed the Arctic clothed in Ventile®.

1980 and 90s

As dyeing houses go out of business, Talbot Weaving, the owners of Ventile, are no longer able to dye and finish Ventile® Fabrics in the UK. Eastern Switzerland has a reputation for quality finishing and Talbot Weaving sends the loom state fabric to Switzerland for final treatment. This arrangement works well but when the Swiss dye house closes, severe quality problems begin. Talbot Weaving tries two further Swiss dye mills but neither of them can achieve effective dyeing and finishing of Ventile®’s dense weave.

1994 – 1995

Stotz & Co. attempt to dye and finish Ventile® fabric, whilst also manufacturing their own equivalent. The company partners with Switzerland’s leading textile finishing expert and, after considerable research, acquires the dyeing and finishing know-how. During the trialling period Stotz & Co. received huge support from the Birkenhead based manufacturer of immersion suits for the Royal Airforce.

1996

The British MoD confirms that Ventile equivalent immersion suits made from Stotz & Co. fabric are of an outstanding quality never seen before. Stotz & Co. decides to extend its supply of performance fabrics to non-military garment manufacturers. With the support of Karol Marketing, a UK based marketing consultancy, the brand EtaProof is created and launched.

1998

Talbot Weaving begins buying white label fabrics from Stotz & Co. and brands these as Ventile.

2017

The owners of Talbot Weaving retire and Stotz & Co. acquires the Ventile® brand.

2018

Stotz & Co. builds upon their keen interest in advanced sustainable textile solutions and invests heavily in developing a range of Ventile Eco fabrics. Initially, the Eco product portfolio consists only of the Ventile Organic fabrics made from organic extra-long-staple cotton but the range expands over the coming years.

2019

Ventile continues to champion the sustainable agenda with its campaign “Join the movement. Love the environment. Choose slow fashion.” The pioneering Eco range grows to offer Ventile Eco Recycled, made from 100% cotton pre-consumer textile off-cuts.

2020

The global textile brand launch Eco Blends, a unique fusion of complementary fibres with high performance and durability at its core. The collection consists of three premium blended fabrics; Ventile Eco Hemp, Ventile Eco Lyocell, and Ventile Eco Linen with all blends chosen due to the minimal impact on the environment.

2021

Ventile make the historic step of moving to a fully PFC-free DWR range, in a move that further reiterates the brand’s commitment to sustainability, the environment, and responsible production processes.

Today

Ventile’s continued commitment to sustainable fabric initiatives is at the forefront of the textiles industry in 2022 with a number of notable achievements for the brand including additions to its ECO collection, record-breaking volume of orders from partners, attendance at global textile shows and unprecedented sales across its collection.